Virtual Problem Solver: The Digital Twin.

Professor Hackensellner, digitization is one of the most important challenges in energy and building technology. This also affects the area of research and development of heat pumps. How do you assess the current status here?

Today, new concepts for heat pumps and questions about system optimization still take place in a development department and in the laboratory. The results lead to a prototype, which then goes through various test phases. This development is cumbersome and time-consuming. From other industries, we know alternative tools and ways with which it is possible to accompany the entire development process digitally and only carry out the complex and cost-intensive measurements using prototypes at a very late stage.

The digitization of devices also offers the possibility of subjecting systems in operation to automated early fault detection and thus avoiding expensive repair costs. In addition, targeted digitization creates the opportunity to integrate findings from the field directly into the development of new products. This shortens development times and strengthens the innovative power of companies.

Today, new concepts for heat pumps and questions about system optimisation still take place in a development department and in the laboratory. The results lead to a prototype, which then goes through various test phases. This development is cumbersome and time-consuming. From other industries, we know alternative tools and ways with which it is possible to accompany the entire development process digitally and only carry out the complex and cost-intensive measurements by means of prototypes at a very late stage.

The digitisation of equipment also offers the possibility of subjecting systems in operation to automated early fault detection and thus avoiding expensive repair costs. In addition, targeted digitisation creates the opportunity to integrate findings from the field directly into the development of new products. This shortens development times and strengthens the innovative power of companies.

The main focus of the research project is to develop a detailed digital representation of an air-to-water heat pump that can be used to significantly shorten long development times. This so-called digital (virtual) twin can be tested directly on the physically existing heat pump.

Basic parameters for the heat pumps are determined on the basis of "hardware-in-the-loop" (HiL) tests. In addition to the metrological analysis, an important component is the most exact possible description of the dynamic and static behavior of the heat pump circuit. Here, a generally valid methodology is to be developed, which also takes into account the use of future refrigerants (e.g. propane) in view of the F-Gas regulation.

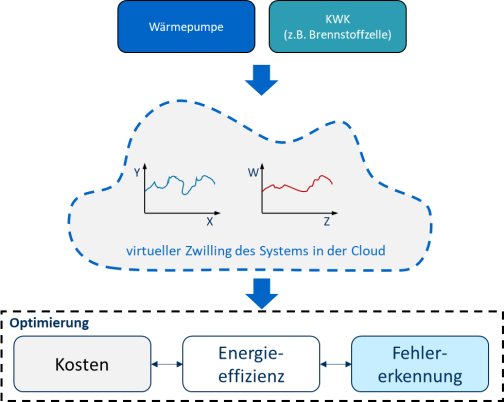

The core of all development work is a cloud environment, which should enable scalability of the results for the entire life cycle of the system.

The main focus of the research project is to develop a detailed digital representation of an air-to-water heat pump, with the help of which long development times can be significantly shortened. This so-called digital (virtual) twin can be tested directly on the physically existing heat pump.

Basic parameters for the heat pumps are determined on the basis of "hardware-in-the-loop" (HiL) tests. In addition to the metrological analysis, an important component is the most exact possible description of the dynamic and static behaviour of the heat pump circuit. Here, a generally valid methodology is to be developed, which also takes into account the use of future refrigerants (e.g. propane) with regard to the F-Gas regulation. The core of all development work is a cloud environment that should enable scalability of the results for the entire life cycle of the system.

Yes, and that in turn creates scope for further innovations. It also strengthens the competitiveness of our company.

The digital mapping of the heat pump under consideration should represent the real physical conditions, such as defrosting or control behavior, as accurately and thus as realistically as possible. This makes it possible to put a heat pump through its paces using defined test scenarios (e.g. start-up behavior, circuit reversal) with digital tools in order to launch a high-quality product on the market. With the digital tools applied, extensive tests of the controller software and hardware can be carried out in GDD's laboratory in a cost-saving manner without lengthy field tests.

What does the customer get out of it?

First of all, this is about simple fault detection during the service life of the heat pump on site at the customer. Real measurement data from the field is recorded and is used to detect any faults that may occur in the future in advance. This enables us to initiate appropriate countermeasures at an early stage.

The research project creates the conditions for offering heat pump users model-predictive control in the future. If you like, it's like looking into a crystal ball - but on a scientific basis. Using a digital heat pump model and suitable predictions of the boundary conditions (e.g. weather forecasts), we are then able to calculate defined scenarios for the future and thus enable, for example, economically optimized operation of the heat pump.

How is the research project designed?

The research project consists of a total of seven work packages that are precisely aligned with the above objectives. In the first work package, the basic principles and the framework conditions for the use cases to be investigated are developed.

The optimization of the defrosting process of an air-to-water heat pump and the optimization of the control of the heat pump circuit and the heating circuit were identified as use cases. Key work packages are the development of a viable software architecture and the modeling of a complete heat pump including control - i.e. the development of the digital twin.

In a further work package, the validation and online operation of the digital twin with the real existing heat pump will take place. During this validation, any deviations between the digital model and the real heat pump are measured and analyzed. Subsequently, the two use cases will be processed in order to gain initial experience with the overall system. The scientific documentation and the transfer of knowledge to the professional world are the task of further work packages.